galvanized sheet zf

introduction

Abstract:

Galvanized sheet zf is a type of steel sheet that has been coated with a protective layer of zinc to prevent rusting and corrosion. In this article, we will explore the various aspects of galvanized sheet zf in detail, including its manufacturing process, applications, benefits, and future prospects. By understanding the properties and uses of galvanized sheet zf, readers can gain valuable insights into this versatile material and its importance in various industries.

1. Manufacturing Process

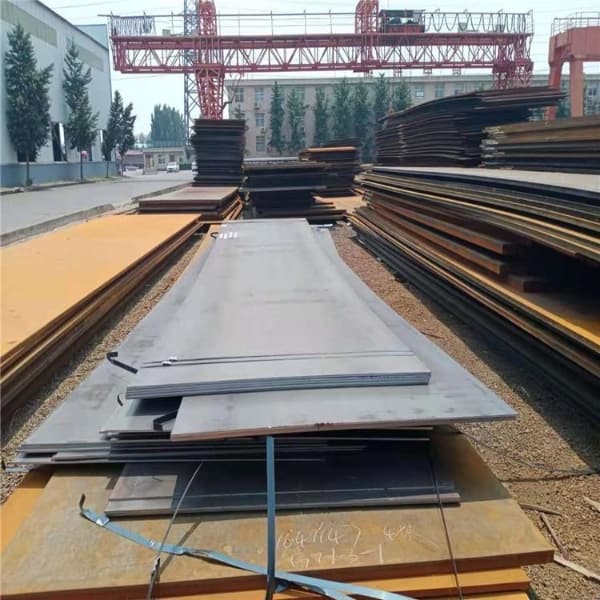

Galvanized sheet zf is produced through a process known as hot-dip galvanizing. This involves immersing the steel sheet in a bath of molten zinc, which forms a metallurgical bond with the surface of the steel. The zinc coating provides a barrier that protects the underlying steel from corrosion, extending its lifespan significantly. Moreover, the process of hot-dip galvanizing ensures uniform coating thickness and excellent adhesion, resulting in a high-quality galvanized sheet zf.

The hot-dip galvanizing process begins with the preparation of the steel sheet, which involves cleaning and pre-treating the surface to remove any impurities. The sheet is then dipped into a flux bath to remove any remaining oxides and promote bonding between the steel and the zinc. Subsequently, the sheet is immersed in a bath of molten zinc at temperatures around 450°C. The coating thickness can be controlled by controlling the speed at which the sheet is withdrawn from the zinc bath. After the galvanizing process, the sheet may undergo additional treatments such as passivation or painting to further enhance its corrosion resistance and aesthetic appearance.

2. Applications

Galvanized sheet zf finds wide application in various industries due to its excellent corrosion resistance and durability. One of the primary uses of galvanized sheet zf is in the construction sector. It is commonly used in roofing, wall cladding, and structural applications, where protection against rust and weathering is crucial. The high strength of galvanized sheet zf also makes it suitable for applications requiring load-bearing capacity, such as bridges, transmission towers, and scaffolding.

Another significant application of galvanized sheet zf is in the automotive industry. It is used to manufacture car body panels, chassis components, and various automotive parts. The corrosion resistance of galvanized sheet zf ensures the longevity of these components, contributing to the overall safety and reliability of vehicles.

Furthermore, galvanized sheet zf is extensively utilized in the manufacturing of household appliances, agricultural equipment, and electrical enclosures. Its corrosion resistance and aesthetic appearance make it an ideal choice for these applications where durability and visual appeal are essential.

3. Benefits

Galvanized sheet zf offers several advantages over other types of steel sheet. Firstly, its superior corrosion resistance significantly extends the lifespan of the steel, reducing maintenance and replacement costs. The zinc coating acts as a sacrificial layer, preventing the underlying steel from coming into contact with moisture and corrosive elements.

Secondly, galvanized sheet zf is environmentally  friendly. The zinc used in the coating is a natural and abundant element, and the process of hot-dip galvanizing has a low environmental impact. Additionally, galvanized sheet zf is 100% recyclable, further reducing its environmental footprint.

friendly. The zinc used in the coating is a natural and abundant element, and the process of hot-dip galvanizing has a low environmental impact. Additionally, galvanized sheet zf is 100% recyclable, further reducing its environmental footprint.

Moreover, galvanized sheet zf provides excellent formability and weldability, allowing for easy fabrication and customization. It can be readily formed into various shapes and sizes without compromising its mechanical properties, making it a versatile material for different applications.

4. Future Prospects

The demand for galvanized sheet zf is expected to witness steady growth in the coming years. Rapid industrialization and urbanization, particularly in developing countries, are driving the construction and infrastructure sectors, thereby increasing the consumption of galvanized sheet zf. Additionally, the automotive industry's continuous growth and the rising demand for durable and sustainable materials will further boost the market for galvanized sheet zf.

Furthermore, ongoing research and development efforts are focused on enhancing the performance of galvanized sheet zf. Innovations in coating technologies, such as advanced alloy coatings or organic coatings, aim to improve corrosion resistance and increase the lifespan of galvanized sheet zf in harsh environments.

In conclusion, galvanized sheet zf plays a vital role in various industries due to its exceptional corrosion resistance, durability, and formability. The hot-dip galvanizing process ensures a high-quality zinc coating that enhances the steel's lifespan and protects it from rust and corrosion. As the demand for sustainable and long-lasting materials continues to rise, galvanized sheet zf is poised to become an integral part of the global manufacturing landscape. Future research and innovations in coating technologies will further enhance the performance of galvanized sheet zf, making it an even more reliable and versatile material for diverse applications.

Leave a Comment