Cooling tower galvanized sheet material

introduction

Cooling Tower Galvanized Sheet Material

Abstract:

This article aims to provide a comprehensive understanding of cooling tower galvanized sheet material. The importance of this material in the cooling tower industry will be highlighted, along with its main characteristics and benefits. By delving into the technical aspects, applications, and environmental considerations, readers will gain valuable insights into the role of cooling tower galvanized sheet material and its impact on the industry.

1. Introduction

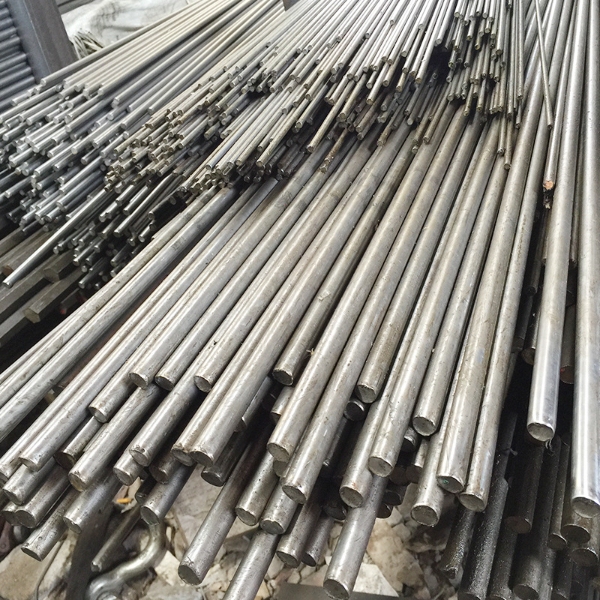

Cooling tower galvanized sheet material is an essential component in the construction of cooling towers. This high-quality material is used to enhance the structural integrity and longevity of cooling tower systems. By providing a brief introduction to the topic, this section aims to captivate readers' interest and provide them with the necessary background information to grasp the significance of cooling tower galvanized sheet material.

2. Importance  of Cooling Tower Galvanized Sheet Material

of Cooling Tower Galvanized Sheet Material

2.1 Structural Integrity:

Cooling tower galvanized sheet material plays a pivotal role in ensuring the overall stability and durability of cooling towers. This section will discuss the importance of using high-quality galvanized sheet material to withstand the demanding conditions that cooling towers encounter.

2.2 Corrosion Resistance:

One of the primary factors that determine the lifespan of cooling tower systems is their resistance to corrosion. By elaborating on the exceptional corrosion resistance properties of galvanized sheet material, readers will gain a deeper understanding of its importance in extending the longevity of cooling towers.

2.3 Heat Dissipation Efficiency:

Efficient heat dissipation is vital for the proper functioning of cooling towers. The use of galvanized sheet material can significantly enhance heat transfer within the system, ensuring optimal cooling performance. This section will explore the reasons behind the improved heat dissipation capabilities of galvanized sheet material.

2.4 Cost-Effectiveness:

Given the long lifecycle and minimal maintenance requirements of cooling tower galvanized sheet material, it proves to be a cost-effective choice for many industries. This section will discuss the financial benefits associated with the use of galvanized sheet material, including reduced repair and replacement costs.

3. Technical Aspects and Applications

3.1 Galvanization Process:

To fully appreciate the benefits of cooling tower galvanized sheet material, it is essential to understand the galvanization process. This section will provide a detailed explanation of how galvanized sheets are manufactured, highlighting the key steps involved and the resulting properties of the material.

3.2 Types of Galvanized Sheet Material:

There are various types of galvanized sheet material available, each with its own unique characteristics and applications. This section will explore the different types of galvanized sheets commonly used in cooling tower construction, such as hot-dip galvanized and electro-galvanized sheets.

3.3 Applications of Galvanized Sheet Material in Cooling Towers:

Galvanized sheet material finds extensive use in cooling towers across various industries. This section will delve into the specific applications of galvanized sheets, including their use in the construction of cooling tower structures, water distribution systems, and fill pack components.

3.4 Environmental Considerations:

As environmental awareness continues to increase, it is crucial to examine the eco-friendliness of cooling tower galvanized sheet material. This section will explore the environmental considerations associated with galvanization processes, including recycling and potential impacts on water quality.

4. Conclusion

In conclusion, cooling tower galvanized sheet material plays a critical role in providing structural integrity, corrosion resistance, heat dissipation efficiency, and cost-effectiveness in cooling tower systems. By understanding the technical aspects, applications, and environmental considerations, professionals in the industry can make informed decisions regarding the use of this material. It is recommended that future research focuses on improving the sustainability of galvanization processes and exploring alternative materials in cooling tower construction.

In summary, cooling tower galvanized sheet material is a vital component that ensures the integrity and performance of cooling tower systems. Understanding its significance, technical aspects, and applications is essential for professionals in the industry. By making informed choices regarding materials, the efficiency and longevity of cooling towers can be enhanced, contributing to sustainable and effective cooling solutions.

Leave a Comment